TecsPak Features

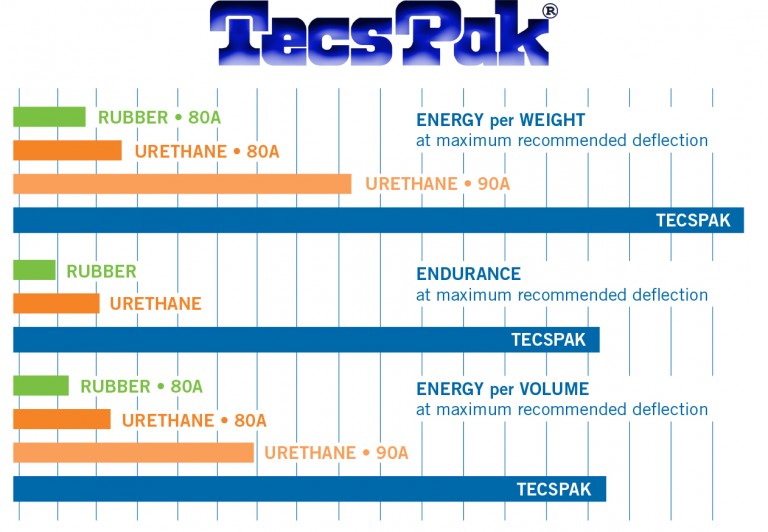

TecsPak® material is a highly engineered elastomeric product that absorbs more energy per unit of weight and volume than many know materials. Below you can find more information about the unique properties that make TecsPak® the number one choice for your energy management problems.

The data tabulated in the PDF Download below summarize the effects of a broad variety of fluids on TecsPak polyester elastomers. As a general rule the resistance of TecsPak elastomers to fluids and chemicals increases as the polymer hardness increases. Unless otherwise noted the

ratings shown in the table apply to all hardness grades.

Rating Key:

A – Fluid has little or no effect

B – Fluid has minor to moderate effect

C – Fluid has severe effect

T – No data – likely to have minor effect

X – no data – likely to have severe effect

Ratings are at 72°F [22°C] unless otherwise specified. Concentrations of aqueous solutions are saturated. Except where noted.

We emphasize that the data contained herein should be used as a guide only. The tabulation is based primarily on laboratory test but

does not take into account all variables that can be encountered in actual use. Therefore it is advisable to test the material under actual

service conditions before specification. If this is not practical, tests should be devised that simulate service conditions as closely as

possible.

Relationships.

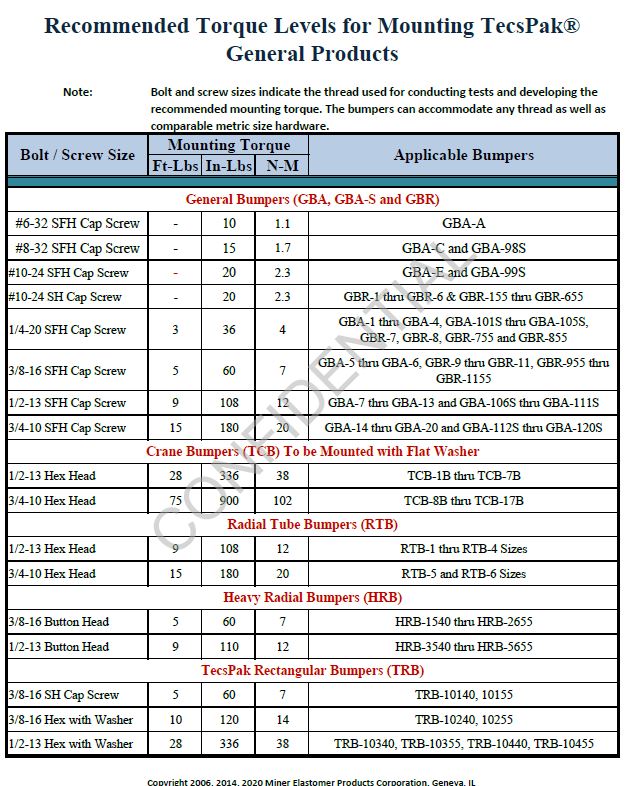

The following are the recommended torque levels for mounting the General Bumper Line products based upon the recommended bolt or screw.

TecsPak® results from taking a selected thermoplastic elastomer and through the use of shape design and patented processing, we obtain a very unique spring material. “Elastomer” is another name for material with rubber-like characteristics. It is elastic, and it stretches. There are two main classes of elastomers: thermoset and thermoplastic. Thermoset elastomers are combined with as many as 30 different ingredients under heat and pressure to give a rubber-like material with more properties than rubber alone. A thermoplastic elastomer melts on exposure to high heat and “freezes” when the temperature drops below the melting point. Thermoplastic elastomers have many of the characteristics of rubber and some excellent properties which rubber does not have.

| Additional features of the TecsPak® products: |

|

TecsPak is a superior elastomer that is not affected by many chemicals and substances typically found in most environments. As such, it will not breakdown over time and become brittle. A typical TecsPak failure mode is not catastrophic in that it will not crack, break or otherwise disintegrate. The failure is more gradual and can easily be planned for and foreseen.

To find out more information download the PDF below.

In general, TecsPak has an excellent fatigue life and will outlive urethanes, rubbers and other elastomers under the same operating conditions. Under typical operating conditions, you can expect an extremely long life from our TecsPak products; in many cases exceeding over 1 million cycles. However, almost every TecsPak application is different in that it has a unique combination of inputs. These inputs include the energy or force input, cycle rate and environmental considerations. Because the combination of these factors that may influence the actual life you experience with TecsPak products we can provide the following considerations.

To find out more information download the PDF below.

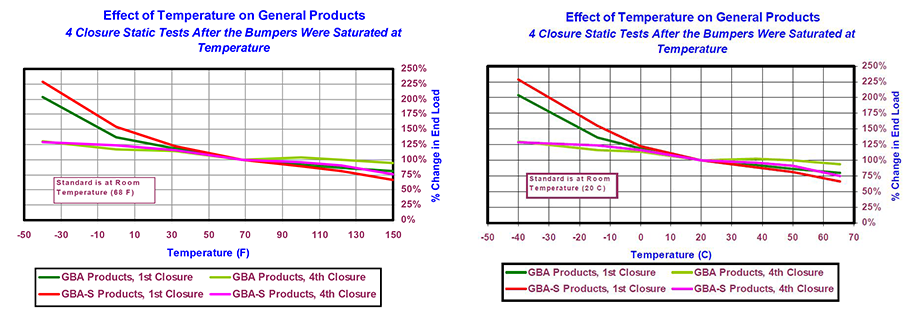

All TecsPak data usually presented for publication is based upon standard tests conducted at room temperature (20°C). However, there are many applications where the product will be used at other temperatures. The following information is to be used a guide in evaluating the effect of temperature in selecting a product.

Background:

TecsPak, like all elastomers, has a variable stiffness based upon temperature. Also, because our material absorbs energy during deflection and converts this energy to heat (hysterisis), the temperature of the material will rise during use. For this reason, as well as others, each bumper was tested four times from the free height to the solid height.

Data:

The chart below shows the effects of temperature on both the GBA and GBA-S product lines. The performance at room temperature is considered the standard (100%) and the peak end loads at various temperatures are then shown as a percentage of this standard.

Thermoplastic Elastomers are measured in Shore A and Shore D according to ISO 868. Shore hardness is a measure of the resistance of a material to the penetration of a needle under a defined spring force. It is determined as a number from 0 to 100 on the scales A or D. The higher the number, the higher the hardness. The letter A is used for flexible types and the letter D for rigid types. Though, the ranges do overlap. This chart shows a comparison of the Shore hardness A and D scales for Apilon 52 TPU materials. Shore hardness reduces as temperature rises.

The following are guidelines that can be used to size TecsPak General Products. TecsPak General Products have been developed to specific energy capacities. However, every application is unique and the bumpers will perform differently based upon the inputs. The guidelines presented are intended to direct you toward a bumper that will be acceptable in the application, but should be proved out to verify that it provides the necessary cushion and life expectancy. The goal of these guidelines is to recommend a bumper(s) that will absorb the energy impacts with a consistent response and with a goal of a one million cycle life.

All standard TecsPak® products, manufactured by Miner Elastomer Products Corporation, have a flammability rating of “HB” for horizontal burn, under UL94 testing protocol. This information is based on information from our raw material supplier. Miner Elastomer Products Corporation makes no independent representations of warranties, expressed or implied, assumes no liability in connection with the use of this information.

Should you have any questions regarding this information please do not hesitate to contact us directly.

TecsPak® has been used in applications in a very wide variety of industries, each with their own requirements and milestones for acceptability. We have been successful in not only meeting, but exceeding these milestones. Listed below is a summary of some typical performance longevity you can expect with TecsPak®. These milestones include industries span a diverse selection of our capabilities. The milestones showcase rebound bumpers in automotive shocks, auxiliary spring on vocational trucks such as cement mixers and heavy mining trucks with payloads in excess of 240 tons.

| Product Application | Performance Criteria | Performance Achieved |

| Mining Struts | 10,000 hours | 20,000 + hours |

| Auxiliary Springs | 3 years or 36K miles | 5+ mil units w/o failure |

| Automotive Struts | 1 million cycles 1 hertz minimum | 10+ mil units w/o failure |

| Class 8 Truck Shocks | 1 mil cycles @ +225 F | 100,000 + units w/o failure |

The increasing use of nuclear energy in power plants, military areas, medicine and other fields places new requirements on many rubber compounds as well as other materials. Some factors of importance to market development activities in this field include, for example: (1) the maximum dosage to which the material can be subjected without damaging effects; (2) the possible use of additives to provide additional stabilization to radiation; and, (3) the effect of radiation on physical properties.

Uncompounded TecsPak polyester elastomers of all three hardness grades have excellent retention of physical properties after irradiation at 23°C. (73.4°F.) in air. (The combined effect of heat-aging or steam-aging concurrent with the radiation exposure was not studied).

Injection-molded 3” x 5” x .075” slabs of the three hardness grades of TecsPak were exposed to a 2 Mev. Electron beam at High Voltage Engineering Company, Burlington, Massachusetts at a dose rate of 10⁵ rads/hour. The slabs were then tested by ASTM methods.

For the most part, radiations of prime interest from the standpoint of insulation damage have energies of order of 1 Mev. These are principally gamma photons and fast neutrons. Damage is caused by collisions of the radiations with electrons and nuclei in the elastomer where the energy input from such collisions may be greater than the bond energies in the elastomer.

Most elastomers are embrittled by radiation exposure, which induces cross-links between molecules. This eventually gives a three dimensional network, such as seen in hard rubber or phenolic resins. A few polymers, notably butyl rubber, degrade by reversion to low molecular weight tars and oils.

Although upgrading changes can occur under controlled low dosage (radiation crosslinked poly-olefins), long exposures normally produce degradation. Thus, the amount of change is dependent on radiation flux rate, total radiation dose, energy of radiation, chemical composition of the polymer, environment (ambient temperature, air vs. inert gas, steam exposure, etc.) and the initial properties of the elastomer compound. The amount of change is independent of the type of radiation at equal energy (Ref. 1), whether alpha, beta, or gamma rays or neutrons. This is known as the equal-energy equal-damage concept.

The table below summarizes the effect of radiation on three hardness grades of TecsPak. It will be seen that the exposure to 10⁷ rads produces very little change in the properties of TecsPak. Test samples are still glossy, highly resilient and flexible after this exposure.

One key advantage with TecsPak is that like most rubbers and elastomers, we have hysteresis which provides a certain level of damping. In fact, compared to most elastomers, TecsPak has a greater amount of hysteresis. As is typical with most elastomers, when they are compressed there is internal friction that generates heat. This heat is energy that the bumper absorbs from the system. Subsequently, the return or release curve has a lower force.

In comparison, a steel coil spring has no hysteresis. When the spring is compressed, it follows a linear line. Upon release, the load deflection curve is the same line as compression.

Typical TecsPak applications involve situations where the bumper is struck by a mass and is used to decelerate the moving object. The object rebounds and the bumper is reset for the next impact or cycle. However, there are many applications where the bumper is used in applications where the bumper is compressed before being further compressed. The compression can be achieved by either a static weight or by physically restraining the bumper at a height.

The following is an explanation highlighting the factors to be considered in applying a TecsPak product for these types of applications.

For the complete report click the “Download” button below: